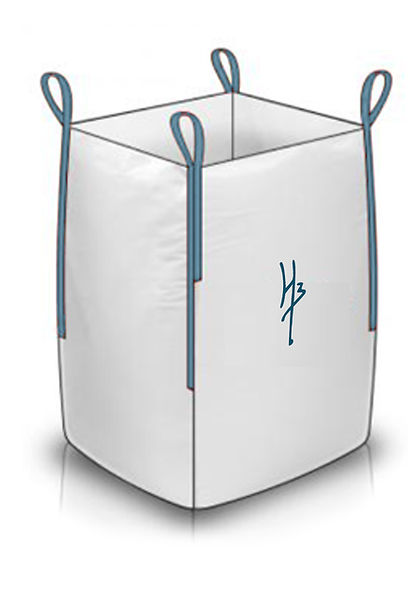

Big bag with 4 handles, U shape panel or tubular uses fabrics from 160g / m2 to 220g / m2, with protection UV.

It is produced with: Open Top, Top Skirt, Loading and unloading valve, Flat bottom, with a safety factor (SF) of 5: 1 (single trip) or 6: 1 (multiple trip).

+ hover over

Big Bags Standard

Brian Hz Design operates with big bags or bags of woven virgin polypropylene, which have handles on the upper part that optimize the loading, unloading and transport of the content.

They can be produced in the form U-panel or Tubular shape

Our big bags can carry lower loads and superior to 2,000 Kg of products or bulk materials.

Brian Hz Design is trained to design the big bag that you require, whether you need valve loading or unloading, skirt top e bottom or flat bottom , ensuring the optimization of your processes, and a packaging to match your company.

Big Bags + LINER

The LINER are an internal polyethylene lining, so that the contained materials do not come into contact with external agents and thus maintain a high degree of purity.

The PREFORMED LINER can have the shape of a hose, or it can have the shape of a bottle at its inlet and outlet, that is, it follows the shape of the Big Bag in its valves, which allows a better flow when loading and unloading the material.

Brian Hz Design is trained to design the big bag that you require, whether you need valve loading or unloading, skirt top e bottom or flat bottom , ensuring the optimization of your processes, and a packaging to match your company.

The thickness or thickness of the inner LINER lining, can be from 60 to 120 microns (my), it is generally 80 m and for Big Bags of more than 1000 kg.

The material is 100% virgin LDPE, the LINER The interior is usually transparent, but it can also be blue or other colors.

+ hover over

Big Bag Mono-handle

The single and double handle big bags represent a special solution for the handling and storage of materials with big bags since one or more big bags can be lifted at the same time with a single hook.

The design can be standardized , allowing for higher levels of automation and efficiency during manufacturing.

The big bags with one and two handles have the body and ties of a single piece of tubular fabric with a weight of 90g / m² at 200g / m².

The bottom is made from a separate piece of fabric square or sewn to the body. This type of Big Bag can be equipped with all types of bottom construction as a valve discharge, flat bottom or others.

It can be a single or DOUBLE HANDLE, which is designed with a grip space between 20cm and 70cm, with a safety factor (SF) of 5: 1 (single trip) or 6: 1 (multiple trip).

You can include LINER with any feature displayed in area by LINERS.